Moulding recycled plastic pellets into products

There are two steps to making plastic bottles, injection moulding and blow moulding.

Step 1: injection moulding to make preforms from pellets

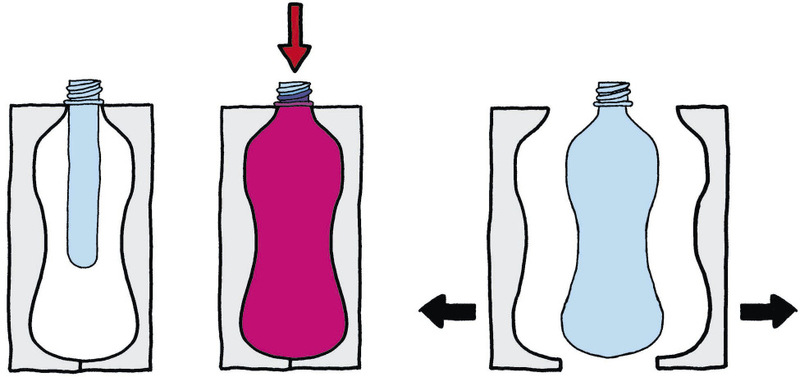

Injection moulding is used to make plastic “preforms” of bottles. Preforms are like small bottles with very thick walls that already have the neck and screw-thread of the final bottle. Figure 1 shows the preform for a plastic bottle.

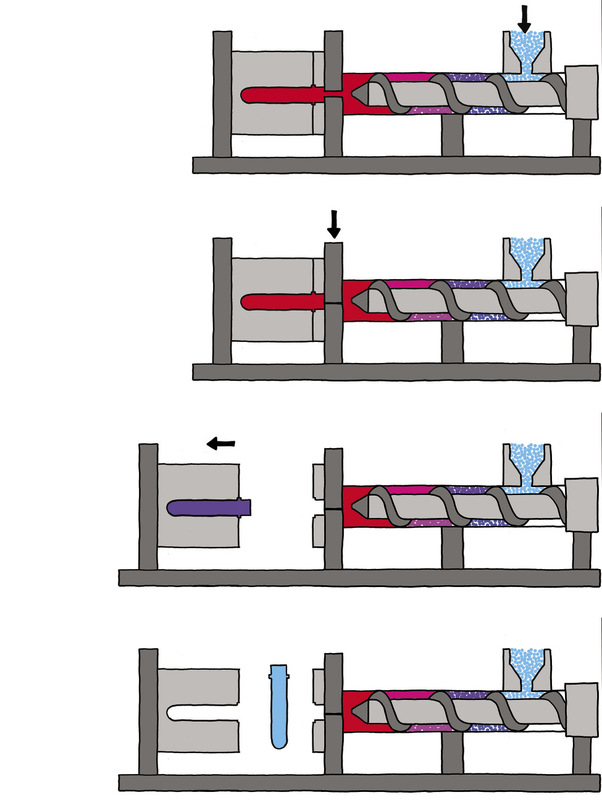

Figure 2 shows the injection-moulding machine at different times of the injection-moulding process. In this picture, the plastic is the coloured substance. The raw material going into the machine is small, almost round pieces of plastic called pellets.

They are initially hard since they have not been heated yet, and are shown in blue. The plastic must be soft and hot for the injection process to work.

The pellets are pushed forward by a screw that is turned by a motor. At the same time, the pellets are heated until they melt. The turning force of the screw creates pressure that pushes or injects the molten plastic into the mould. Once the mould has been filled, the opening of the mould where the molten plastic came in is closed, and the mould is left to cool.

The plastic in the mould solidifies as it cools down. Once it has cooled down sufficiently, the two halves of the mould open so that the preform that was made can be taken out.

Answer the following question in connection with Figure 2.

1. Find the mould and label it.

2. Where will you put a heater on the machine to melt the plastic pellets? Draw an extra part or parts for the machine to show where the heater should be, and label it.

3. Look carefully at a plastic bottle. You will find a very thin ridge where the two parts of the mould joined. If you cannot see it, feel around the neck of the bottle with your finger.Why is the mould line on both sides of the neck?

Step 2: blow moulding to shape preforms into bottles

Next, the preform goes to a blow-moulding machine. This machine blows hot air under high pressure into the preform. This heats the lower part of the preform so that it becomes soft and can change its shape. The high air pressure forces the walls of the preform to expand into the mould, similar to blowing up a balloon.

The same type of preform can be made into different shapes of bottles, since it can be blown into different moulds. But all the bottles will have the same screw-on cap.

1. Why will all the different-shaped bottles fit the same cap?

Recycling plastic to make new products

In Chapter 9, you learnt why we should recycle plastic containers and other products. In this chapter, you will learn how PET plastic can be recycled and made into a new raw material.

Case study: the cyclical process of recycling plastic

1. Why should plastics be separated into different types before it can be recycled?

2. How do the recycling codes on the plastic containers help to sort them?

3. The containers are not only plastic. If you look carefully at a container, what other materials can you find? You can look at some of the containers your classmates brought to class.

4. Are all the plastic containers in the bin clean? Is this important?

5. Plastic bottles and other containers take up a lot of space. Why is this a problem?

6. Name four things that need to be done to plastic waste before it will be suitable to turn into new products.

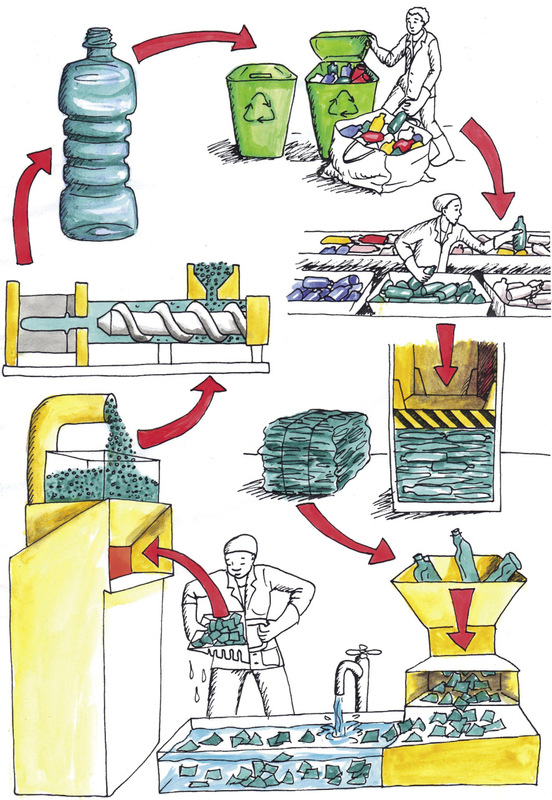

The illustration on the next page shows the plastic recycling process.

Each type of plastic waste is pressed into bales that can easily be transported. At the recycling factory, the plastic waste is shredded into small pieces, to make it easier to handle and wash.

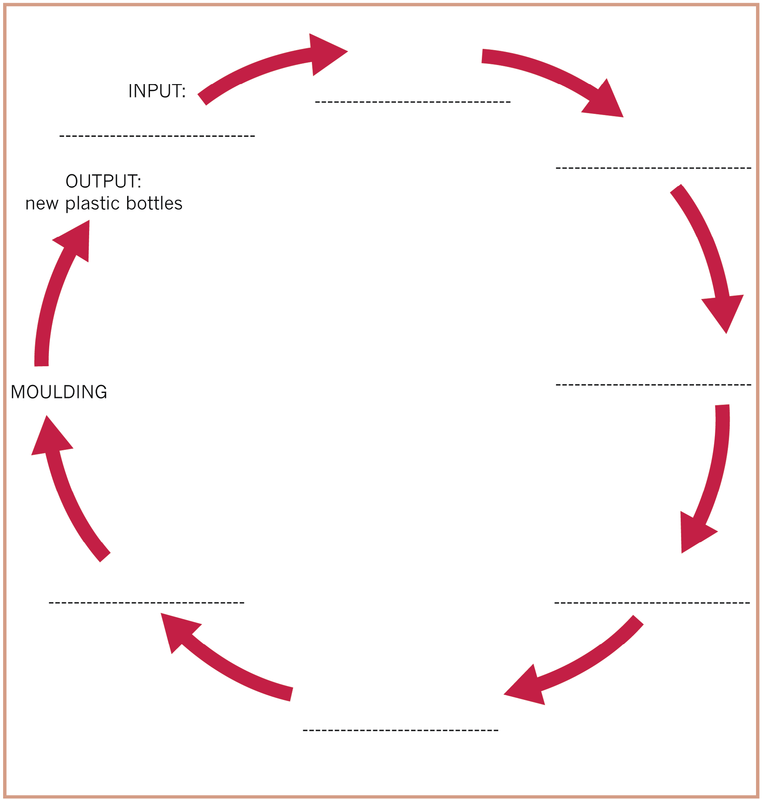

7. Complete the systems diagram below by giving descriptions of the different steps of the recycling process. Hint: When something is recycled, it means that the output is also the input, since the process is a cycle or circular.

What have you learnt?

1. What is the raw material for the bottles in this process?

2. How can consumers and house-owners make it easier for recyclers to process plastic products to make new bottles?

3. A manufacturer can buy one type of preform and then make different-shaped bottles. How can this be done?

4. Which type of moulding do you think is used to make plastic chairs?

5. What is the difference between injection moulding and blow moulding?

Subscribe to our WhatsApp channel to get the latest posts delivered right to your dm.

Comments